Wardley Electronics Ltd – Sub Contract Manufacturer of electronic assemblies

Electronics Manufacturing is our speciality. Our high standards of Quality and Service have helped the company to grow steadily, primarily through word of mouth recommendation.

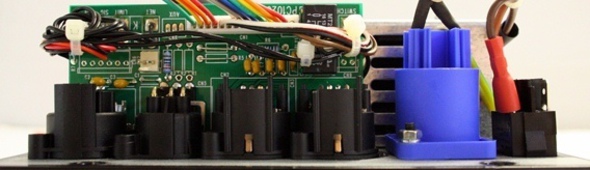

Surface Mount assembly is performed on our fast and flexible Surface Mount line. It comprises of a DEK265 and a Quad printer, two Mirae pick and place machines and a ten zone forced air convection Heller reflow oven. The quality of it's output is 100% checked by our Cyberoptics AOI.

Wardley can also fit conventional components quickly and accurately. Our team of highly skilled and experienced operators are assisted by Contax semi automatic placement machines. We solder using our CMS400 wave solder machine, Pace Irons and our most recent acquisition, a Pillarhouse selective soldering machine. Our solder processes have been fully ROHS compliant since 2006.

Mechanical Assembly, case build and final test is performed in our dedicated, 3000 sq ft assembly area. We move components from their store along our assembly lines, through final test to the clear areas where complete pallets are built up and shipped.

Component Purchasing and sourcing has become a key part of the service we offer our customers. We are able to consolidate our buying, increasing our purchasing power to achieve better pricing. Even in the difficult conditions of recent years, we have been able to source full kits of parts, but still at competitive prices, to keep our customers supplied with product.

About us

Discover the advantages of working with us, the unique quality of our production methods and the skills of our team.