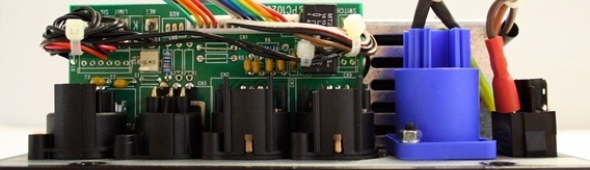

Surface Mount Assembly

Surface Mount assembly is one of the cornerstones of our successful manufacturing business. Quality, Accuracy and Speed are key.

Surface Mount Assembly is performed on our fast and flexible Surface Mount line.

Solder Paste is accurately printed on one of our two machines. We have a fully automatic DEK265 and a semi-auto Quad printer. We can also hand print small quantities of boards.

Surface Mount placement is performed on our two Mirae pick and place machines. The 1010 is a high speed chipshooter, the 1030P is a flexible placer. Between the two, we can achieve fast turn-round of multiple small batches or high speed volume manufacturing.

Surface Mount soldering is done in our Heller 1800. It’s a ten zone forced air convection reflow oven.

The overall quality of our Surface Mount output is 100% checked by our Cyberoptics AOI. We adopted this fully automatic surface mount inspection in 2010. Our surface mount quality is now so reliable, we have dropped many of the board level PCB tests we used to perform as they have simply become unnecessary.

We hold stock of thousands of high quality surface mount components. Many

of our customers allow us to supply parts for their boards from our stock. Many of these parts are permanently set up on our feeders, so we can consolidate and set-up quickly. We achieve this by

stocking the highest quality parts, for example, we only hold 1% MFR resistors and we always use X7R for the higher capacitor values. We don’t charge the premium price, as we benefit from the reduced

changeover times. It’s just an example of how we can work with our customers to ensure mutual benefit.

Interested?

We're always happy to discuss our extensive range of products. Contact us on 01473 809296 or use our contact form.